Industrial IoT Management Platforms

Discover the future with BrenPower: Revolutionizing your world with cutting-edge Industrial Internet of Things (IIoT) solutions. Maximize energy efficiency, streamline maintenance, harness time effectively, and embrace eco-friendly practices. Start your journey to sustainability and operational excellence with us today. Are you ready to transform?

Request a PoC

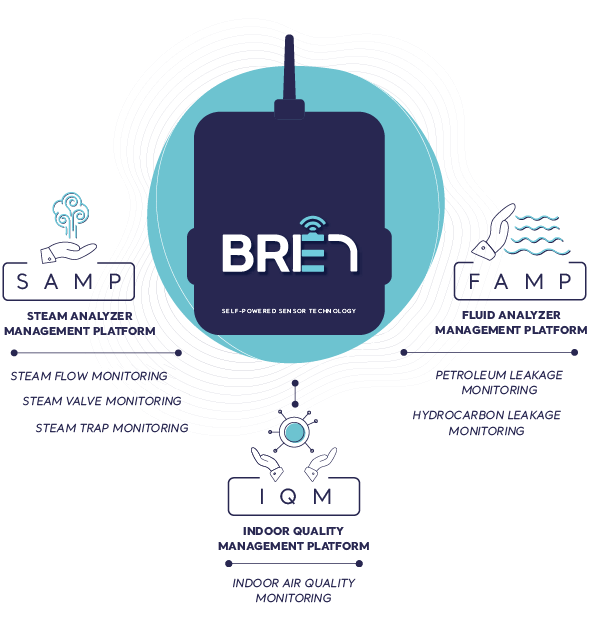

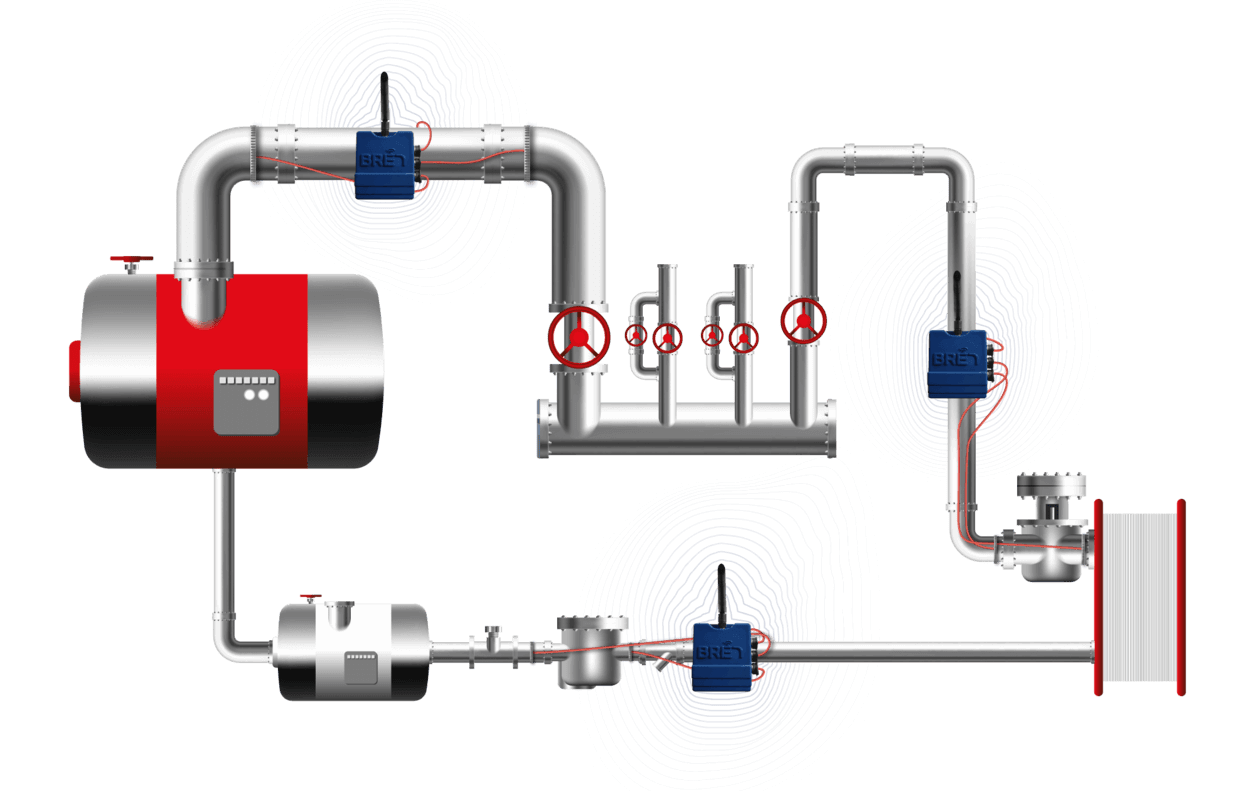

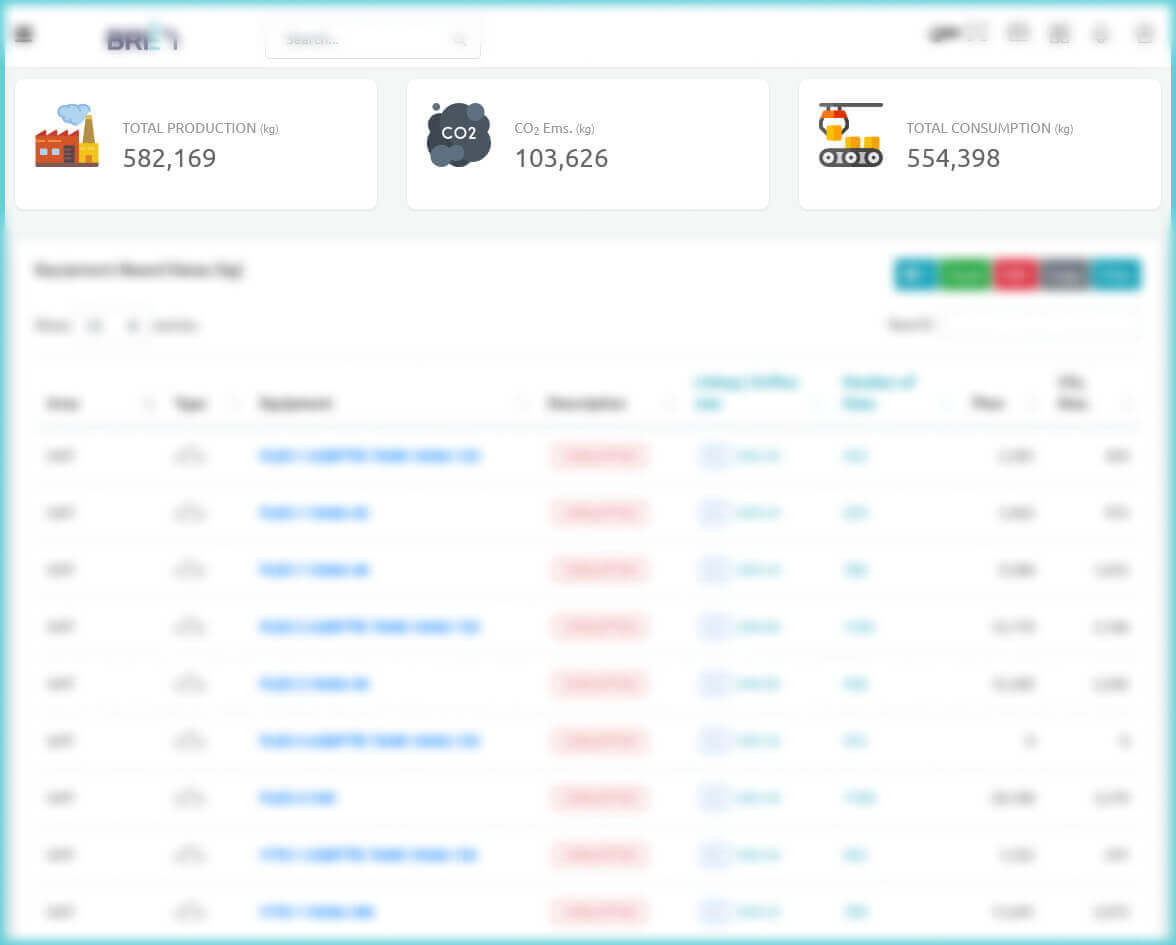

Steam Analyzer Management Platform (SAMP)

End-to-end monitoring of the entire steam line

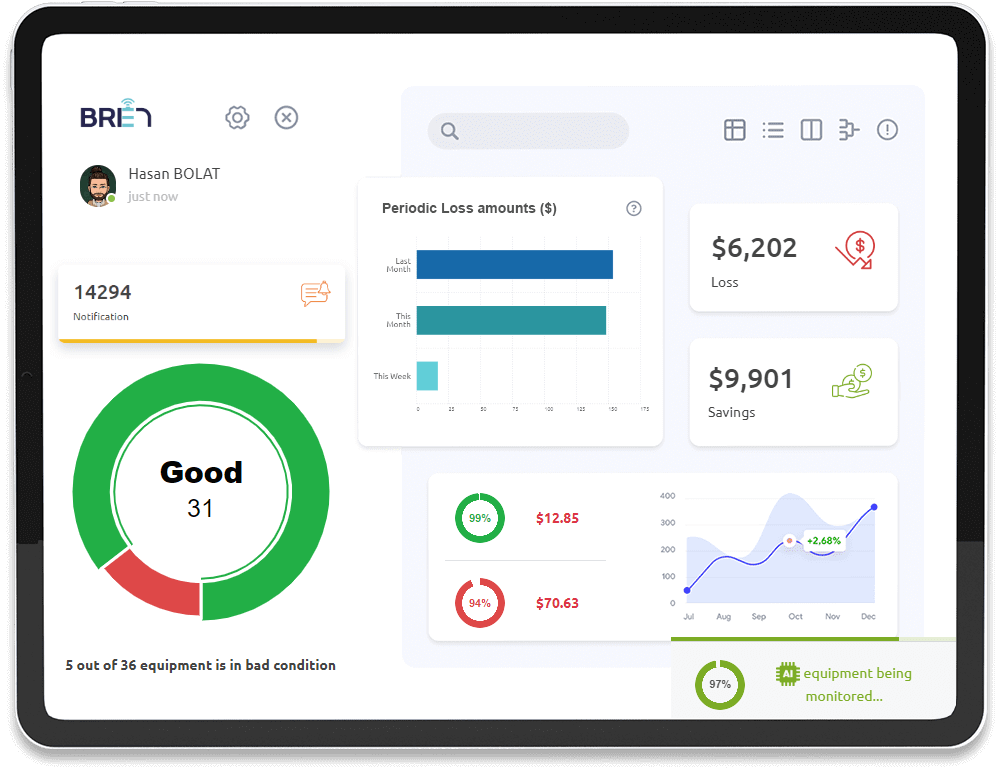

Mega Scalable IIOT Platform

with battery free sensors for remote monitoring

Software-Based Subscription Tiers

Users

Notifications

Reporting

Reporting

Steam Traps Leakage

Steam Valve Leakage

Hydrocarbon Leakage

Petroleum Leakage

Indoor Quality Monitoring

Steam Flow Monitoring

Steam Valve Monitoring

Monthly Automatic Reporting and Recommendation

Smart Insulation Management

Enhancing Sustainability With Data-Driven Insights

Accurate Notifications for Leakage Detection with Cost Calculation

Smart Insulation Management & Steam Quality Control

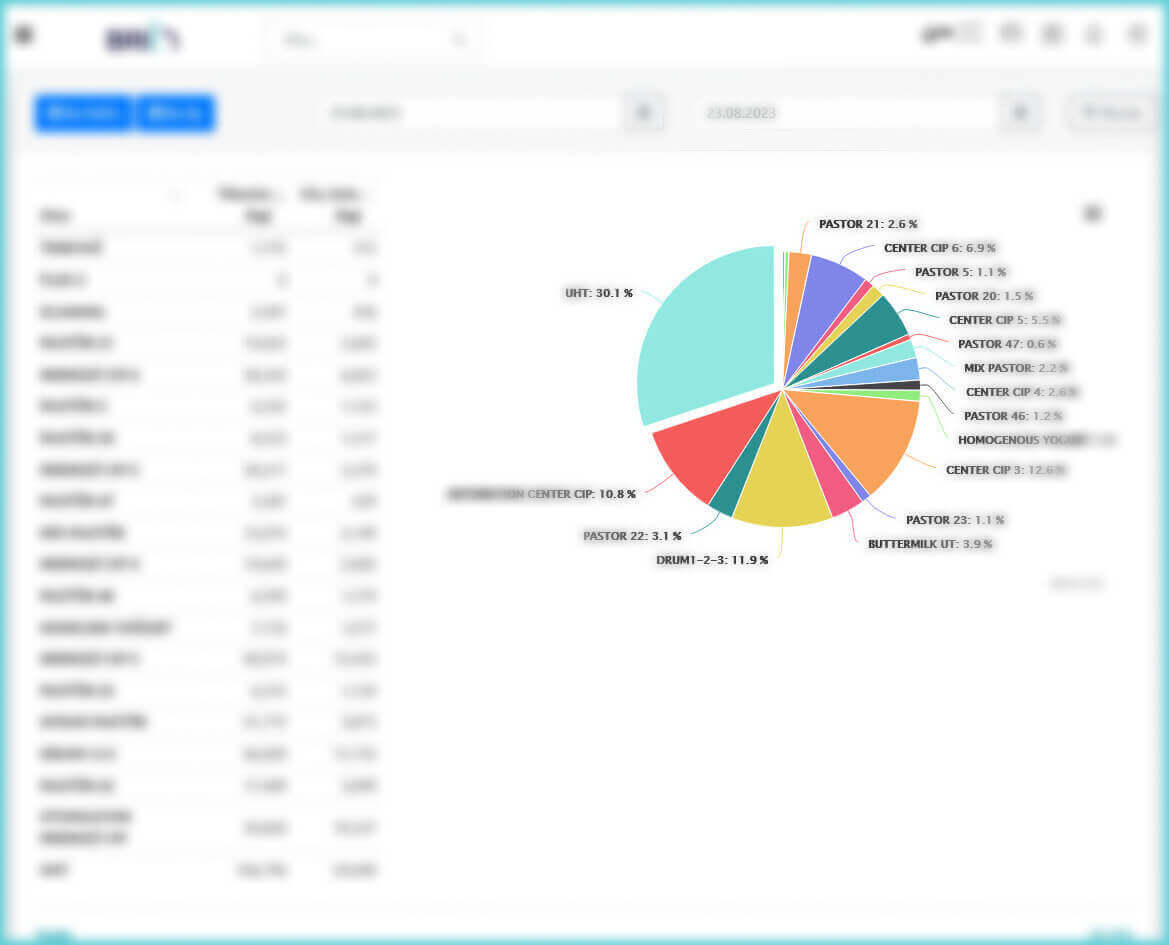

Streamlining Steam: Optimize & Report Emissions

Steam Mass Balance & Carbon Emission Report

Testimonials

We are immensely pleased with our adoption of the Brenpower Steam Analyzer Management Platform (SAMP) and Indoor Quality Monitoring (IQM) systems. These innovative solutions have been pivotal in optimizing our energy efficiency and minimizing our environmental impact. By enabling continuous monitoring and analysis of critical parameters such as indoor air quality and steam flow, they empower us to make data-driven decisions that significantly contribute to our sustainability objectives. The integration of these systems into our operations has not only enhanced our operational efficiency but has also reinforced our commitment to environmental stewardship.

Our team is thrilled with the implementation of the Brenpower Steam Analyzer Management Platform (SAMP) for end-to-end steam monitoring. This integrated solution has been a game-changer for us, significantly boosting our operational efficiency, enhancing energy conservation, and reducing carbon emissions. With Bren SAMP, we're not just optimizing our operational performance; we're also making a tangible contribution to environmental sustainability. It's rewarding to see the direct impact our work has on both the planet and our company's efficiency.

We've been extremely impressed with the Brenpower steam monitoring solutions. The Steam Analyzer Management Platform (SAMP) was a breeze to install, requiring no modifications to our existing lines, which was a huge plus for us. It's not just about efficiency; it’s about smarter, sustainable operations. SAMP has transformed the way we operate, cutting down our reliance on external energy sources and slashing our carbon emissions in a big way.

What really stands out is Brenpower's commitment to sustainability, integrating cutting-edge AI technology and self-powered modules into SAMP. This approach doesn’t just meet our sustainability goals; it propels us forward. It’s incredible to see such a significant environmental impact from a platform that also boosts our operational performance.

We couldn't be happier with Brenpower's Indoor Quality Monitoring Platform (IQM). Leveraging IIoT and AI technologies, IQM enables us to keep a constant eye on crucial factors like ambient temperature and air quality, making our operations run smoother and more efficiently. The benefits we've seen have been substantial and incredibly positive. What's more, their steam trap monitoring system has been a game-changer for us, ensuring that every aspect of our operation is optimized for peak performance. It's clear that Brenpower's solutions are not just about monitoring; they're about empowering businesses like ours to reach new heights of efficiency and sustainability.

Integrating Brenpower’s Steam Analyzer Management Platform (SAMP) into our power plant operations has been a transformative experience. The platform’s real-time flow monitoring and instant notifications have revolutionized our approach to operational efficiency. Thanks to SAMP, we can now quickly detect and address blockages and steam leaks, which has significantly enhanced our energy efficiency. This digitalization effort not only optimizes our maintenance routines but also aligns perfectly with our goals for increased energy efficiency in the power plant. It’s clear that SAMP is an essential tool for modernizing our processes and achieving sustainability targets.

At SOCAR Refinery, embracing Brenpower's steam trap and valve monitoring platform has been transformative. This innovation hasn't just propelled us towards unprecedented operational efficiency; it has significantly aligned our processes with our commitment to sustainability. The real-time monitoring and analytics have drastically cut down our energy use and maintenance costs – a testament to the platform's efficiency.

The ability of this platform to predict and prevent issues is nothing short of essential in our refinery's demanding environment. Its intuitive design and the outstanding support have made integration and daily operation seamless. Brenpower hasn’t just given us a tool; they've provided a pathway to greener, more sustainable refining practices.

For refineries prioritizing not just cost-effectiveness but also environmental responsibility, Brenpower’s platform is not just beneficial – it's vital.

Adopting Brenpower's SAMP and FAMP platforms has significantly elevated our operational strategy, particularly with steam trap monitoring taking center stage. This focus has revolutionized our energy efficiency and digitalization efforts. SAMP's real-time monitoring enhances our processes, while FAMP's swift leak detection ensures our operations are seamless. The standout, however, is the steam trap monitoring feature, which has been instrumental in identifying inefficiencies and preventing energy loss. This has not only streamlined our operations but also underscored our commitment to sustainability and technological advancement.

Integrating Brenpower’s Steam Analyzer Management Platform (SAMP) has been a revelation for us, particularly in tackling issues like blowdown valve leakage, which is critical in our operations. This platform has not only helped us detect and address such leaks swiftly but has also played a pivotal role in enhancing our overall operational efficiency. What’s more, by minimizing these leaks, we’ve seen a significant reduction in our carbon emissions. It’s impressive how SAMP has empowered us to not only fine-tune our operational performance but also contribute positively to environmental sustainability. It’s clear that with tools like SAMP, we’re making substantial strides in energy efficiency and reducing our environmental impact.