The Magical Transformation of Steam: A Paper Mill's Energy Efficiency Adventure

Challenge

In a large paper mill, in an environment where steam is used intensively, there was no existing steam monitoring system. This made it very difficult to accurately calculate the amounts of steam produced and consumed. This deficiency prevented an assessment of how efficiently the steam produced was being used, making it difficult to identify potential improvements to save energy. One of the biggest challenges facing the factory is managing the efficient generation, utilization and recovery of steam. Maintaining a uniform temperature across the surface of the roll is a critical element for the production of quality paper. Effective monitoring and control of these complex processes is essential for the efficient use of energy.Plant management was looking for a solution to meet these challenges and manage steam systems more effectively. When they discovered the Steam Analyzer Management Platform (SAMP) steam monitoring solution from Brenpower, they knew immediately that it had to be implemented across their entire plant.

Solution

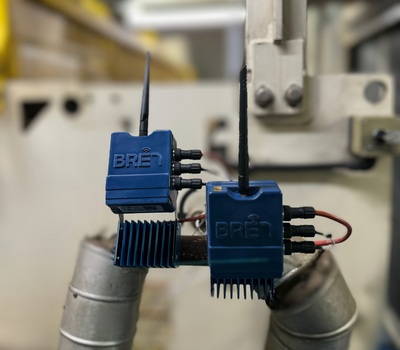

To address these challenges and improve energy efficiency, the mill turned to Brenpower's Steam Analyzer Management Platform (SAMP). SAMP initiated a major transformation in paper production by providing the ability to comprehensively monitor and manage the mill's steam system. Wireless IoT monitors were integrated into steam traps, valves and main lines, enabling instant monitoring of steam flow from production to consumption points.

To address these challenges and improve energy efficiency, the mill turned to Brenpower's Steam Analyzer Management Platform (SAMP). SAMP initiated a major transformation in paper production by providing the ability to comprehensively monitor and manage the mill's steam system. Wireless IoT monitors were integrated into steam traps, valves and main lines, enabling instant monitoring of steam flow from production to consumption points.

SAMP also laid a foundation for future AI plans by showing how steam pressure levels affect the cost and efficiency of the system. With this system, the factory received instant failure alerts, resulting in energy cost savings. Product output was more consistent and of higher quality because the behavior of the steam and processes were continuously monitored.

Benefits

- Operational safety has increased thanks to instant fault alerts along with energy cost savings. Instant monitoring of steam behavior and processes improved product quality and increased customer satisfaction.

- With the Steam Analyzer Management Platform (SAMP), an infrastructure was created for future artificial intelligence plans, and the factory embarked on a journey of continuous improvement.