Step into Operational Excellence

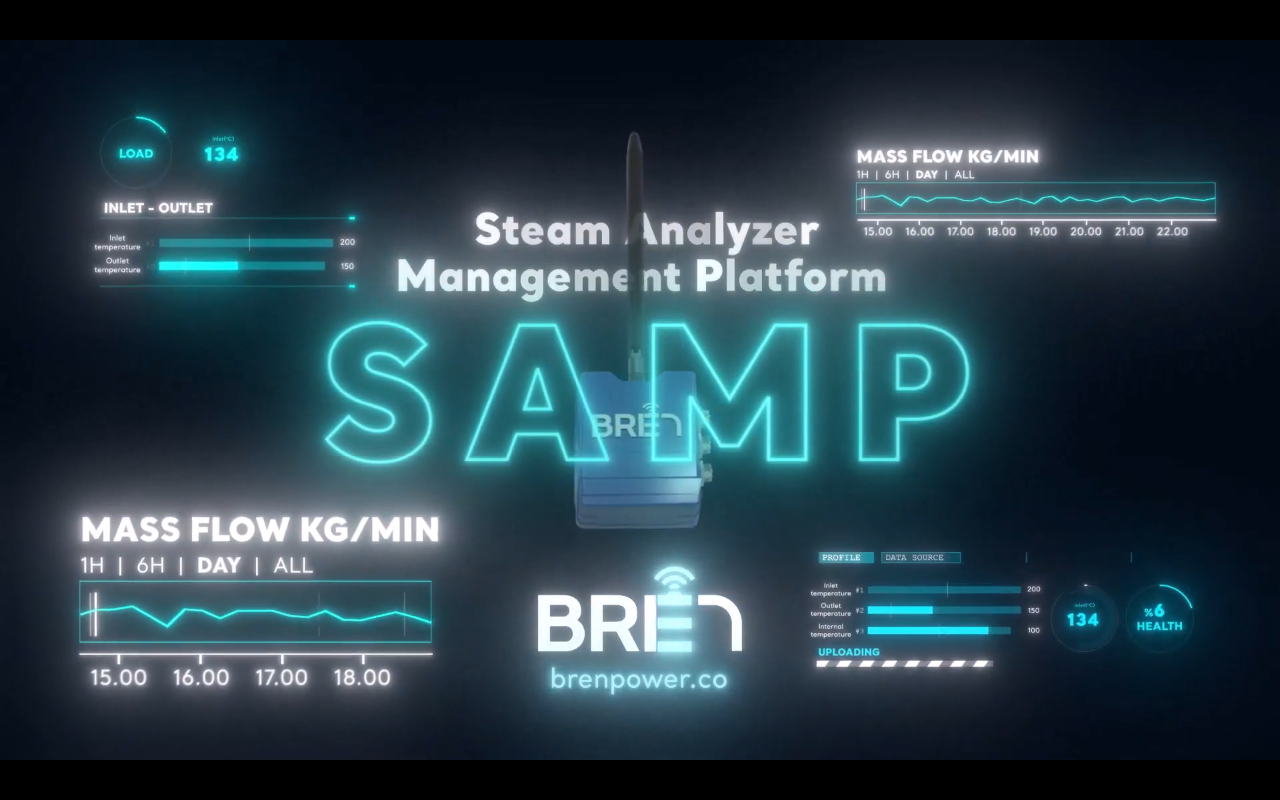

Prevent energy losses, optimize your processes, and take control with real-time data.

A smart solution for seamless monitoring and maximum efficiency. Enhance your production environment.

Monitor your system in real-time, detect leaks, and transition to a sustainable manufacturing process with advanced technology that improves steam and energy management!

Our software infrastructure is exciting in terms of user experience and efficiency.

Proven Transformation, Achieve Real Impact

Explore our success stories across different industries and discover the real impact of our solutions on the shop floor. Real data, tangible results! Check out our case studies now.

INDUSTRY: Oil & Gas

Challenge

Frequent hidden failures in steam traps and valves caused energy waste, safety risks, and unexpected downtime in critical lines. Undetected steam leaks and uncontrolled condensate discharge reduced boiler efficiency and caused a significant rise in natural gas consumption.

INDUSTRY: Food & Beverage

Challenge

Frequent hidden failures in steam traps and valves caused energy waste, product quality issues, and unplanned downtime in production. Undetected steam leaks and uncontrolled condensate discharge increased utility costs and negatively affected both energy management and steam quality.

INDUSTRY: Tyre Manufacturer

Challenge

Unmonitored steam traps and bypass valves led to hidden steam leaks, condensate accumulation, and steam hammer incidents — resulting in excessive energy use, production inefficiencies, and equipment stress during vulcanization and curing processes.

INDUSTRY: Chemical Industry

Challenge

In chemical manufacturing plants, undetected steam trap failures led to energy inefficiencies, temperature control issues in reactors, and increased operational costs.

INDUSTRY: Automotive Manufacturing

Challenge

Steam leaks and unmonitored condensate systems caused production delays, increased energy costs, and equipment wear in automotive manufacturing plants.

Our Care

Boost efficiency, reduce costs, and optimize operations with Brenpower’s real-time monitoring and actionable insights

Plug & Play Installation

Seamless integration into existing systems. Rapid deployment with zero disruption. Retrofit-friendly for older infrastructure

Real-Time Monitoring & AI-Powered Analytics

Live dashboards for steam traps, air quality, energy use. AI-driven insights to detect anomalies and inefficiencies. Custom alerts and maintenance forecasting

Production-Linked Cost Tracking

Input production volumes to calculate: Per-unit utility consumption. Total run cost per batch or shift. CO₂ emissions per product. Optimize process economics and increase visibility

Reduce Utility Costs

Save on steam, electricity, water — minimize waste through continuous monitoring and AI-driven optimization.

Sustainability & ESG Compliance

Track carbon footprint, automate reporting, support net-zero goals with comprehensive analytics.

Modular & Scalable Deployment

Retrofit easily, integrate with existing systems, scale across multiple sites with plug-and-play architecture.

Bespoke IoT Sensors + AI

Custom-engineered sensors tailored to your specific industrial processes, powered by advanced AI for superior diagnostics and optimization.

Actionable Analytics & Alerts

AI-based anomaly detection, customizable alerts, real-time dashboards for immediate action.

Brenpower Showcased AI-Powered Digital Twin Solutions at ZELLCHEMING Expo 2025

From July 1–3, 2025, Brenpower proudly took part in ZELLCHEMING Expo 2025 in Wiesbaden, Germany — one of Europe’s leading events for the pulp, paper, and industrial process sectors.A

Brenpower AI Successfully Showcased Energy Efficiency and Sustainability Solutions at Go Energy Turkey Fair

From May 8th to 10th, 2025, the Go Energy Turkey Fair took place at the Bursa Fair Center, gathering leading companies and innovators in the energy sector. Brenpower AI proudly took part in this key e

Energy Inefficiencies and the Importance of IoT, and Brenpower's Solutions

Energy management is crucial for businesses to reduce costs and achieve sustainability goals. In particularly energy-intensive steam systems, inefficiencies can negatively impact business performance.