Chiller Monitoring

Smart solutions that enable real-time monitoring of chiller systems to improve energy efficiency and detect faults before they occur.

Risks That Undermine Cooling Performance

Efficient and stable operation of chiller systems is critical for cooling performance, product quality, and energy costs. However, traditional monitoring methods fall short of continuous performance tracking. Brenpower addresses these challenges with real-time data tracking, AI-powered analytics, and automated reporting infrastructure.

Lack of Data Access: Silently Growing Energy Losses

Key parameters such as temperature, pressure, and energy consumption are often collected manually or via local systems, which limits holistic analysis and causes efficiency losses.

Incompatibility of Analog Systems with Digital Monitoring

Conventional systems are hard to monitor in real time and cannot be integrated with modern analytics platforms, delaying detection of faults and inefficiencies.

When Does Actual Efficiency Slip Away?

If a chiller runs continuously with the same energy input, its COP may decrease over time. When such losses aren't monitored instantly, hidden costs arise.

Don’t Just React — Predict and Prioritize

Manual observation carries error risks. Sudden changes and faults may not be detected in time, leading to reactive rather than proactive maintenance approaches.

A New Era In Chiller Monitoring With Brenpower

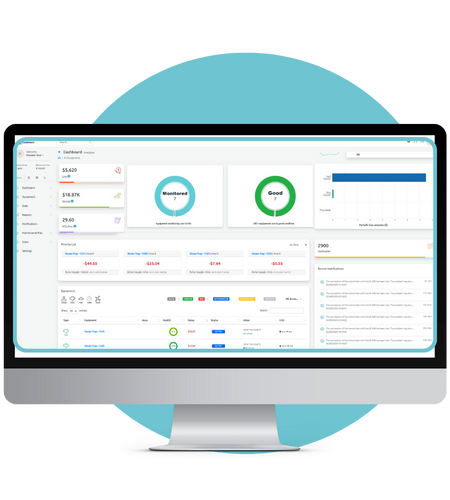

Real-Time Monitoring, AI-Based Analytics, and Automated Reporting

- Make Cooling Performance Instantly Visible

Brenpower tracks key parameters like evaporator/condenser temperatures, pressures, and COP values in real time, enabling early detection of performance deviations and preventing energy waste.

- Algorithms That Detect Failures Before They Occur

Historical data from chiller systems is analyzed by AI algorithms to predict efficiency drops, overloads, or freezing risks — allowing maintenance before unplanned downtime occurs.

- Monitor COP Live and Catch Losses Instantly

COP (Coefficient of Performance) is calculated live. Instant drops in COP help identify periods of low efficiency quickly.

- Keep Your Cooling System’s Pulse

Potential issues like compressor overload, condenser clogging, or evaporator icing are detected early, extending equipment life and enhancing system reliability.

Create Value With Automatic & Detailed Reporting

Ready for Audits with Automatic Reporting

All performance data is archived by the system. Automatically generated weekly and monthly reports provide audit-ready insights on energy efficiency, system health, and carbon emissions.

Wherever You Are, Your Chiller is With You

Thanks to Brenpower’s cloud-based structure, all chiller systems across different facilities can be monitored from a single central panel. Instant performance data is accessible from mobile and desktop devices.

Turn COP and Consumption Data into Insightful Reports

Brenpower transforms collected chiller data into meaningful reports that help assess performance, optimize energy use, and identify improvement opportunities.

Daily Operation and COP ReportsVisualized data including working hours, real-time COP, inlet-outlet temperatures, and energy usage.

Monthly Comparison of Electricity Consumption vs Cooling CapacityCompare energy consumed with cooling output on a per-facility basis.

KPI-Based Reporting: kW/ton, kWh/cooling capacityTrack system efficiency through energy KPIs.

Automated Email NotificationsScheduled weekly or monthly reports are sent to users automatically.

Learn more about "Chiller Monitoring"

You can access our documentation and promotional materials from the links below.

Brochure

Ask for a Quotation