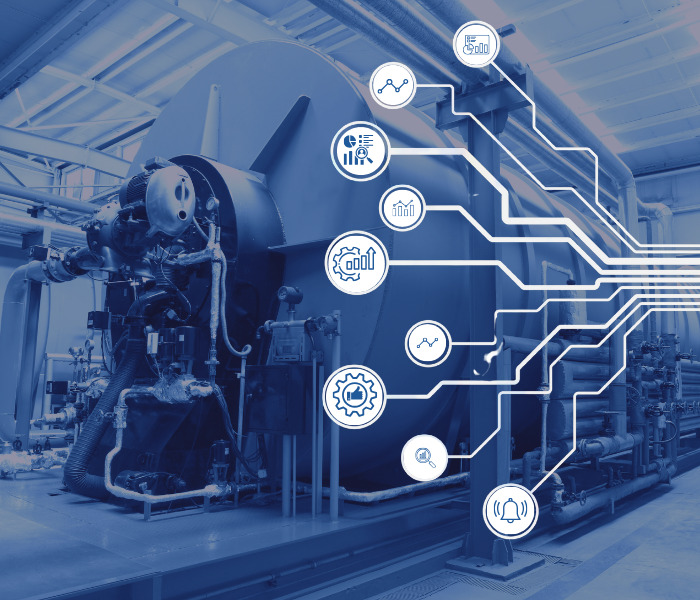

Boiler Efficiency Monitoring

The Boiler Efficiency Monitoring system analyzes real-time performance data to detect energy losses. This helps improve efficiency, prevent unnecessary fuel consumption, and avoid potential failures.

Operational Challenges

Efficient management of boiler systems is critical for controlling energy consumption, process efficiency, operational safety, and overall cost. However, traditional monitoring methods are often insufficient for optimizing these processes. BrenPower addresses these key issues through real-time data tracking, AI-powered analytics, and automated reporting.

Scattered and Incomplete Data Collection

Key parameters such as steam flow, steam pressure, steam temperature, feed water temperature, and natural gas consumption are often collected manually or via local systems. This results in delayed, incomplete, or unanalyzable data, leading to efficiency losses.

Legacy System Integration

Manual indicators and non-digital infrastructures make it difficult to monitor boiler efficiency in real time. Sudden anomalies in the process may go unnoticed, resulting in energy waste and decreased productivity.

Lack of Energy Efficiency Tracking

Without knowing the efficiency of a boiler at different times of the day, it's impossible to perform energy optimization. Systems that continuously burn gas without monitoring performance may experience unseen efficiency drops and cost increases.

Manual Checks and Observations

Manual monitoring and reporting are prone to human error and provide no real-time alerts. This leads to overlooked efficiency losses, unplanned downtime, and delays in maintenance operations.

Revolutionize Boiler Management with Real-Time Insights and Predictive Intelligence

With a data-driven approach, achieve maximum efficiency and minimal energy loss. BrenPower combines IoT technology, AI-supported analytics, and remote access capabilities to solve the main challenges in boiler efficiency monitoring. Our platform provides full transparency into real-time steam production, natural gas usage, and overall energy efficiency—empowering businesses to prevent efficiency losses, optimize processes, and reduce operational costs.

- Real-Time Monitoring

Instantly monitor key metrics such as steam flow, pressure, temperature, and natural gas consumption to assess the energy performance of your production processes. Real-time tracking enables you to detect inefficiencies early and ensure maximum process stability.

- Predictive Maintenance

Leverage historical performance data and AI-based analytics to predict potential efficiency drops in boilers. Plan maintenance activities proactively to avoid unexpected failures and reduce both downtime and costs.

- Energy Efficiency Audits

Compare real-time consumption and production ratios to measure the boiler system’s energy conversion efficiency. Identify periods of excessive fuel use or low steam output to drive sustainable improvements and cost savings.

- Performance-Based Process Management

Continuously evaluate how boilers perform under load to understand system durability and operating characteristics. This analysis helps identify upgrade opportunities and supports optimal planning for modernization investments.

- Compliance and Audit Reporting

Regularly archive and report energy usage, steam generation rates, and carbon emission data. These automated reports ensure compliance with energy management standards and environmental regulations, providing full audit readiness.

- Global Access

Access boiler performance data from anywhere in the world using BrenPower’s cloud-based system. Monitor live performance and historical trends remotely, allowing seamless operational control regardless of physical location.

BrenPower Integration

BrenPower’s system directly integrates with boiler control panels, enabling real-time data transmission. It supports widely used communication protocols such as RS485, Modbus, and 4–20 mA, allowing seamless data collection of critical parameters such as steam flow, pressure, temperature, feedwater temperature, and natural gas consumption. All collected data is securely transferred to BrenPower’s cloud infrastructure over an internet connection. Advanced data processing algorithms then calculate real-time boiler efficiency and generate actionable insights. Our solution offers uninterrupted data communication via 4G LTE, Ethernet, or Wi-Fi connectivity. Data security is ensured through AES256 and RSA encryption protocols, maintaining high-level protection across all operations.

Powerful Reporting and Analytics for Data-Driven Decision Making

Get a complete overview of your boiler’s energy performance with specialized reports that analyze efficiency, usage patterns, and operational behavior. These insights help identify improvement opportunities and enable effective cost control strategies.

Operational and Efficiency Reports

Analyze boiler activity by tracking run-time hours, efficiency fluctuations, temperature changes, and fuel usage behavior. Daily steam production performance is evaluated alongside critical variables to detect inefficiencies early.

KPI-Based Performance Reports

Key performance indicators (KPIs) such as specific gas consumption, energy per kg of steam, and carbon emissions are continuously measured. Long-term trends are tracked to guide strategic decisions with reliable data.

Automated and Scheduled Reporting

Weekly and monthly reports are automatically sent via email. This structure eliminates manual follow-up and enables continuous monitoring with minimal effort, ensuring users are always prepared for audits and process optimization.

Learn more about boiler efficiency monitoring

You can access our documentation and promotional materials from the links below.

Brochure

Ask for a Quotation