Steam Trap Monitoring

Brenpower Steam Trap Monitoring instantly detects leaks and failures in your steam systems, preventing energy losses. With AI-powered analytics, it optimizes maintenance processes and boosts sustainability and efficiency in production.

Challenges In Steam Trap Monitoring

Operational Challenges Limited and Irregular Data Flow In manual monitoring methods, data is only captured at the moment of inspection, with long intervals in between. This makes it impossible to detect steam trap leaks, blockages, or malfunctions in real time. As a result, hidden energy losses occur, increasing overall operating costs.

Limitations of Legacy Systems

Many facilities operate with outdated systems or manual inspections that offer limited visibility. This leads to delayed fault detection, persistent inefficiencies, and rising maintenance costs. Legacy systems also pose risks to process safety and disrupt operational continuity.

Hidden Energy and Steam Losses

Steam trap failures or malfunctions often go unnoticed and result in significant energy losses. These losses increase operational costs and raise carbon emissions, undermining sustainability efforts. Continuous, real-time monitoring of these losses is essential for improving energy efficiency and protecting profitability.

Risks and Limitations of Manual Measurements

Manual measurement methods require hot pipelines to obtain accurate readings, making field operations more difficult and reducing measurement frequency. A steam trap may fail shortly after a manual inspection, going undetected until the next one, resulting in continued energy loss. Manual data collection introduces human error, increases the risk of overlooked warnings, and causes inconsistencies in the system.

Transform Steam Trap Management with Real-Time Insights and Predictive Intelligence

Brenpower’s AI-powered online monitoring system addresses the key challenges in steam trap management. Our platform provides full visibility into steam trap performance, energy usage, and maintenance needs, helping businesses reduce unplanned downtime, prevent energy losses, and improve operational efficiency.

- Real-Time Monitoring

Track inlet and outlet temperature values and pipe vibration data in real time to ensure optimal steam trap performance and prevent energy losses. Instantly detect leaks, failures, and water hammer effects as they occur.

- Predictive Maintenance

Analyze historical temperature and vibration data using AI to predict potential steam trap issues before they arise. Plan maintenance proactively to minimize downtime and reduce energy loss.

- Energy Efficiency Checks

Continuously monitor system performance to identify inefficiencies, reveal hidden steam losses, and optimize energy use—ultimately reducing operational costs.

- Steam Trap Performance Management

Analyze steam trap behavioral trends to detect early signs of performance decline. Evaluate risks in advance and anticipate failures to enhance system safety and process efficiency. Make timely maintenance and replacement decisions, supported by predictive maintenance strategies.

- Compliance Reporting

Automatically record and report steam trap performance data to support audit readiness and alignment with energy management and sustainability standards.

- Global Access

Monitor and manage your steam traps remotely with secure cloud infrastructure. Track system performance in real time, whether on-site or off-site, and maintain full operational control anytime, anywhere.

Features

Data-Driven Reporting and Analysis for Steam Trap Performance Management

Reports

Comprehensive Reporting and Instant Alerts.

Gain a complete picture of your steam trap system performance with detailed reports covering failures, energy losses, and environmental impact. These reports support fast, informed responses by decision-makers to enhance efficiency and streamline maintenance strategies.

Weekly Failure and Carbon Emissions Reports

Receive automated weekly summaries detailing trap performance and estimated carbon emissions caused by steam leaks. Monitor not only energy losses but also environmental impact to drive sustainability improvements.

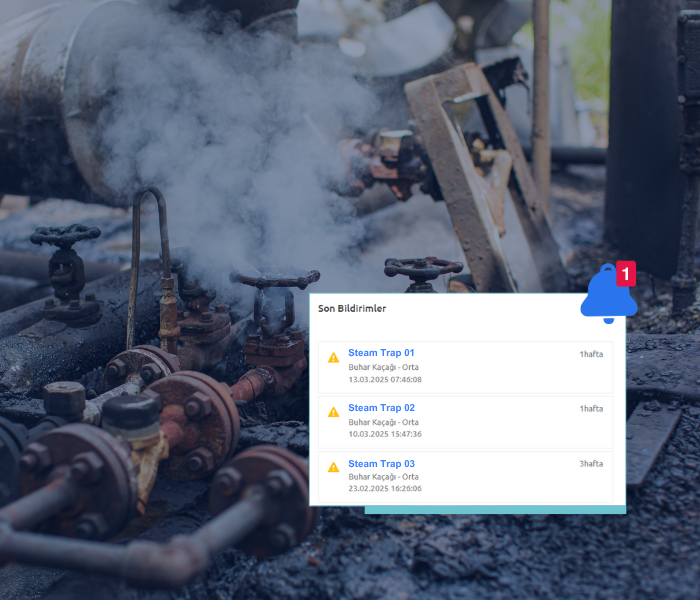

Instant Failure Notifications

Get immediate email and SMS alerts when the system detects steam leaks, blockages, or abnormalities. Maintain process security and reduce the risk of unplanned shutdowns.

KPI-Based Performance Tracking

Track key performance indicators such as energy efficiency, failure frequency, system health, and environmental metrics. Use data-driven insights to support continuous improvement and strategic planning.

Automated and Scheduled Reporting

Weekly reports are automatically delivered via email, eliminating manual follow-up and enabling continuous oversight of system performance.

Learn more about "Steam Trap Monitoring"

You can access our documentation and promotional materials from the links below.

Brochure

Ask for a Quotation