Compressed Air Monitoring

Compressed Air Monitoring is a smart monitoring system designed to improve energy efficiency and reduce operational losses in industrial air compressor systems.

Challenges in Factories

Air compressors are among the highest energy-consuming equipment in industrial facilities. However, they are often overlooked in monitoring strategies, leading to significant inefficiencies.

High Energy Consumption, Low Visibility

Compressors run constantly, consuming large amounts of energy, yet how much is actually used effectively remains unknown.

No Pressure or Flow Monitoring

Without monitoring pressure and flow rates, leaks, pressure fluctuations, and overloads in the air distribution system go unnoticed.

Leaks and Unnecessary Usage Go Undetected

Micro-leaks in the pipelines or open air valves may waste thousands of euros worth of energy per year. Without real-time monitoring, such losses persist silently.

Inefficient Operation Cannot Be Detected

Issues such as excessive start-stop cycles, poor pressure settings, or improper load conditions remain hidden without load/unload cycle tracking or operational data.

Proposed Solution: Smart Compressed Air Monitoring System

Our system provides real-time visibility into the performance and energy efficiency of air compressors, helping reduce operational costs and avoid failures.

Real-Time Monitoring

Key data such as power consumption, load hours, pressure, flow rate, and temperature is continuously tracked and logged.

Leak and Pressure Drop Detection

The system detects unexpected drops in pressure or abnormal flow during non-production hours, helping identify leaks quickly.

Energy Efficiency Calculations

KPIs such as specific energy (kWh/m³), load/unload ratio, and compressor performance are calculated automatically to track efficiency.

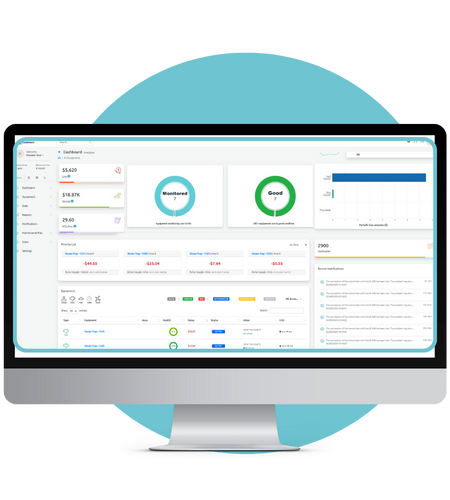

Web-Based Dashboard and Alarm System

All data can be securely accessed via a web-based panel. Alerts are generated for pressure drops, overconsumption, or equipment failures.

Wireless Data Transmission

Using LoRaWAN or NB-IoT technology, data is transmitted wirelessly, making the system quick to install without disrupting production.

Reports and Key System Features

Our platform transforms collected data into actionable insights and comprehensive reports, enabling smarter decision-making.

Energy Consumption Reports

Generate daily, weekly, or monthly reports showing electricity usage, load/unload ratios, run hours, and air production volume.

Leak Detection Reporting

Analyze night-time and idle-period flow data to pinpoint possible leaks or inefficiencies in the air distribution system.

Performance & Health Analytics

Track trends such as increasing power usage or decreasing flow rate to detect maintenance needs before failures occur.

PDF & Excel Report Export

Reports can be downloaded in Excel or PDF formats, and automatic email reports can be configured for stakeholders.

Learn more about "Compressed Air Monitoring"

You can access our documentation and promotional materials from the links below.

Brochure

Ask for a Quotation